You love your wine. We all do. Did you ever wonder how that luscious liquid gets in that bottle? There is a lot of effort and time put into ensuring you enjoy your sips and swirls. But we do love doing it and as saying goes, “Choose a job you love, and you will never have to work a day in your life.” Let’s just see what it takes to go from grape to glass.

The first decision is are you going to be a grower/winemaker or just a winemaker. Well, Mike and I do not want to be farmers. We are true believers in letting the experts do what they do best. We will stick to making the wine and letting the farmers do what they do best. And we are thrilled with our farmers. So let’s skip the part of growing. The lifecycle of the grape, and the concept of Brix (sugar content) to choose when to harvest could be a whole other post…. UMMM, tuck that thought away for future reference, more science never hurt anyone. This post is going to begin with harvest.

De-Stemming

Once the fruit is picked and trucked to the winery the first thing that we do is de-stem the fruit. Very simply this means to separate the fruit from the rachis (stem). Although this could be done by hand, and take forever, there is a machine that shakes the fruit and does the de-stemming. All we do is stand at the end and pick out any of the MOG (material other than grape) Here is a video of the de-stemmer.

Crush

After de-stemming, the winemaker may choose to crush, not crush or partially crush the fruit. This is the process of breaking the skin of the fruit. Generally this has an impact on color and flavor. Traditionally, men and women did the harvest dance to crush the fruit and release the precious juice. We do not do that, most places do not, unless it is done ceremoniously.

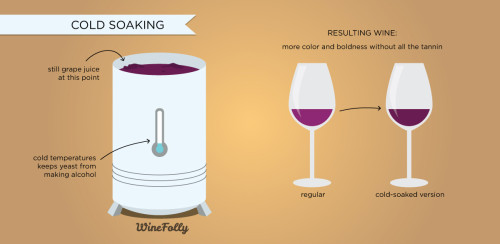

Maceration

This is the point in wine making where white and red wine vary. Since allowing the juice to 'sit' on the skins provide color and tannic structure to the wineClick To Tweet white winemakers may choose to quickly press the must (freshly pressed fruit juice that contains the skins, seeds, and stems [if not de-stemmed] of the fruit) after crushing in order to separate the juice from the skins, seeds, and solids. Generally and overly simplifying, the longer the juice sits on the skins the deeper color the wine will be. (other factors can inhibit or enhance wine color)

During maceration, there most likely will be must adjustmentsClick To Tweet and dry ice is added to keep the temperature of the must cool. Chaptalization, adding sugar (illegal in the CA and Southern Europe) may occur in cooler climate areas where the fruit had difficulty ripening. Acidity adjustments may be made by adding tartaric or malic acid, typically in warmer climate areas where the malic acid may be consumed by the grape during the later stages of ripening. Nutrients are often added along with sulfur dioxide to suppress the natural yeast and bacteria on the fruit and inhibit the oxidation of enzymes. If the fruit is overripe, sometimes water will be added to lower the sugar level.

Pressing

Pressing is the process of separating the liquid from the solids. Typically, white wine is pressed immediately after crush, while red wine is pressed after fermentation. The process of pressing produces “free run.” This is the juice that comes out of the press without the use of pressure and winemakers may choose to separate the liquid according to its press fractions.

1- free run

2- light press

3- heavy press

4- hard press (high in tannin and generally not used in finished wine)

Enzyme addition is also done during the press. This is done to possibly increase press yield, especially with white grapes. The most frequently used enzymes are pectinases that break down the skin’s integrity, glucosidases which help to release terpenes that lead to the floral aromas (especially in muscat-type wines) and color enzymes to increase color and increase tannin extraction in red wines.

Fermentation

Fermentation, the magic behind winemaking. Click To Tweet The process that will occur all on its own if let be. Between the natural (native) yeast in the air and on the fruit, the yeast will begin to break down the sugars in the juice and produce alcohol and carbon dioxide as byproducts. Some winemakers choose to allow the natural yeast to perform this job, while others, like us, suppress the natural yeast and inoculate with a chosen yeast strain. We do this to eliminate surprises in the process. If all goes well, fermentation will continue until all the sugar is converted to alcohol, producing a dry wine. If a sweet wine is desired, the fermentation will be manually stopped prior all the alcohol being converted.

Fermentation can be done in tanks, open containers, or barrels. A newer trend is using concrete fermenting tanks since they dissipate heat and are useful for tannin and color extraction. Managing the temperature during fermentation is extremely important. If the temperature rises too high, the yeast will begin to die off and fermentation will be halted.

A secondary fermentation known as Malolactic Acid Fermentation (MLF) may occur. In MLF malic acid is converted to lactic acid.Click To Tweet Lactic acid is softer tasting than the tart malic acid. MLF enhances the body and flavor of wine, producing wines that tend to be softer and more well rounded on the palate. Many winemakers also feel that better integration of fruit and oak character can be achieved if MLF occurs during the time the wine is in barrel. Additionally, MLF allows for microbiological stability and imparts a buttery flavor into the wine. Wines that typically undergo, and are improved by MLF, are the full-bodied dry whites and medium to full bodied dry reds. If MLF is not desired, sulfuric acid can simply be added.

**The sequence of Pressing and Fermentation switches depending whether it is a white or red wine. A white wine will press then ferment,while a red wine will ferment then press.

Aging

After fermentation is completed and the wine is racked several times to remove the largest solidsClick To Tweet the young wine is not quite ready to be consumed. It needs a little time to settle and develop. This is the process of aging and is typically done in stainless steel, cement lined vats, or oak barrels. The most common oak choices are French, American or Hungarian. The winemaker may choose to use neutral or new oak. If using new oak, the winemaker can choose a toast level. All of these decisions impact the end result of the wine. You can read about the production of wine barrels in my three part series about cooperage.

The barrel itself allows oxygen to enter the wine at an extremely slow pace. (a little oxygen is good for wine, a lot is trouble) and does impart some oak character into the wine. It is generally thought that if you get 50% of the extract the barrel has on the first use and 25% on the second use. After the second year, the barrel is considered neutral. While in barrel, the wine will go through slight chemical changes to create a more complex wine with less harsh tannins.

Depending on the winemaker’s philosophy and what varietal, the wine may sit in barrels for anywhere between six months to two years. In fact, some wineries hold their reserve wines more than that. Typically speaking, white wines age less time than red wines.

Bottling

We all know what bottling is. It’s sealing the fabulous fluid into a container preparing it for consumption. Most wine is consumed shortly after purchase (within 10 years) so aging in bottle really is not that big of an issue. The most common bottle size is 750 ml (approximately five 5 oz pours.)

The process is relatively simple. Larger wineries may have their own bottling line, but since the equipment is extremely expensive, many wineries choose to use a mobile bottling line. A tractor trailer pulls up to your winery with all the equipment inside. The empty bottles arrive on pallets and are loaded onto the bottling line. The bottles go through a wash and then nitrogen is injected into the bottle to expel the oxygen. Before running the line, a measuring level is set so that a precise amount of wine is distributed into each bottle. The wine, that is being pumped over from the barrels is then perfectly placed into the bottles. Once the wine is in bottle, it moves down the line to have the corks inserted and the capsule is placed on top and sealed. Continuing down the line, the label is placed on each bottle. [as a side bar, since we learned the hard way. The labeler either unrolls to the right or left. Your labels need to be wound the correct way or else the labels won’t go on correctly. If this occurs, be prepared to spend the next several hours re-winding your labels. Then expect to need a massage after your arms and shoulders are dead] Once the labels are on the bottles continue down the line, are removed from the belt and replaced into the cases.

There is some debate over whether or not bottle shock is a legitimate concern. The belief is that bottle shock can occur not only directly after bottling, but after the wine has been shipped. Although there isn’t any scientific proof, many people have experienced a flat or muted wine directly after receiving it. The theory is that motion and heat can stress all phenolics and chemical compounds that make up the wine. Do I believe in bottle shock? Being a scientist, it is tough to believe in something that can not be proven, but as a winery owner, I’m not taking that chance, so our wine sits for several months before we release it. We also do not drink a wine immediately after it has been shipped to us. [although I’m not sure that is because we think of bottle shock or we just don’t want to drink a wine we just received.]

Returning to the quote in the opening statement, I can honestly tell you that is the truth. Running the winery is not an easy job, and trying to run it when you are bicoastal adds a little more adventure, but there is no doubt about it, I love it, and would rather spend every waking moment dealing with the winery than anything else and I never feel like it is work.

~Sláinte!

Great explanatory article! Well done and easy to digest!

Thank you Michelle

What a great education. The time and care taken to provide a very complex and scientific methodology in laymans terms is great!

Thank you so much Trinice. I love trying to make the science easier. And thank you for your wine order! Hope all is well with you!