Cooperage, what the heck is it? It is a cool name and it’s even a cooler job. If you love wine, you need to learn the science behind the wine barrel. Have you ever watched the show, How It’s Made on the Science Channel or Sport Science on ESPN? I love shows like that. I am mesmerized by the science behind things. To me, nothing occurs without science working in the background. If you read my blog in the past, you know that there are several posts dedicated to science. They say you have to stick to what you know, and I know and love science. In this series, I’m going to talk about Cooperage. Cooperage is the art, yes art, of making barrels. There is a lot of science behind the wood that is used to make the barrel, any old wood won’t do. Once the wood is chosen, the art of cutting, bending and aging the barrel is mind-blowing. Purchasing an oak barrel today runs in the neighborhood of about $800 – $1200. If the winemaker is spending that much money on a single barrel, he is expecting an exceptional product. It is truly a special talent to craft a barrel, and in these next few blog posts, I’m going to discuss the process. The first post, as always with me, focuses on the science.

Mike and I both have worked in R&D. (Research & Development) There is something special about walking into a store and seeing “your product” on the shelf. You take pride in it, because a lot of time, thought and effort went into developing it. When you work for a large corporation, you sign off that whatever you create while under their employment is theirs to own. So all you are left with is the pride. I have to admit, it is pretty cool and I’m not going to lie, we have been known to walk into a store and see “our product” hidden behind an aisle display and accidentally move the display in front of another product. So I wonder, do Cooper’s feel this same pride? I ponder, do the Coopers taste a bottle of wine from a winery that they sold their barrel to and go- “Yeah, that’s my work in there?”

There is a direct effect on the taste of the wine depending on the wine barrel chosen by the vintner. There are levels of toast, American vs. French vs. Hungarian oak barrels, so there is a lot to consider. But whatever barrel is chosen, I can guarantee there was someone’s heart and soul went into making it. Taking on the endeavor of creating (and I use creating purposely, because making just isn’t the correct term) a barrel is a long and arduous process. It is one that I would believe you have to love in order to choose it as a profession. A process that once again, incorporates art and science.

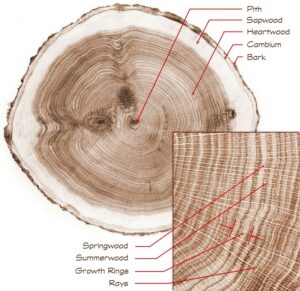

As with corks, like I discussed in a previous post, Quercus is also the preferred oak used cooperage production. The white oa k contains the properties necessary to provide a tight cooperage while possessing the subtle fragrance that has become expected in the barrels. There are four types of wood found within a tree. Sapwood, typically lighter in color adds support to the tree and is used in the transportation of nutrients. Heartwood is typically darker because of the presence of tannins, and the presence of cells that are no longer active. Springwood, is what you would thing- the new growth. It is the rapid growth stage and consists of large cells with thin walls. Summerwood, occurs when the Springwood rapid growth slows down. These cells have thicker walls, and are tightly packed. Slow-grown wood is slightly softer, making it more pliable than the wood that has grown rapidly. Other than the growth rate differences, structural and chemical differences occur throughout the tree. Oak lactones and vanillin also vary across the wood. American oak tends to possess less extractable phenolics than European oaks and tannin levels vary significantly. The use of the different oak to create the barrels will deliver different results to the winemaker.

k contains the properties necessary to provide a tight cooperage while possessing the subtle fragrance that has become expected in the barrels. There are four types of wood found within a tree. Sapwood, typically lighter in color adds support to the tree and is used in the transportation of nutrients. Heartwood is typically darker because of the presence of tannins, and the presence of cells that are no longer active. Springwood, is what you would thing- the new growth. It is the rapid growth stage and consists of large cells with thin walls. Summerwood, occurs when the Springwood rapid growth slows down. These cells have thicker walls, and are tightly packed. Slow-grown wood is slightly softer, making it more pliable than the wood that has grown rapidly. Other than the growth rate differences, structural and chemical differences occur throughout the tree. Oak lactones and vanillin also vary across the wood. American oak tends to possess less extractable phenolics than European oaks and tannin levels vary significantly. The use of the different oak to create the barrels will deliver different results to the winemaker.

As with everything else, all wood is not created equally. Not all wood can be made into a barrel. Wine cooperage requires specific properties. It must have vessels and fibers that run parallel to the length of the trunk, with no waves within the growth pattern and can not have vessels that intertwine. These would lead to flaws in the barrel. The wood must possess strength and resilience, and lack any faults that could cause leakage. Extremely important is the lack of any off odors. The cooper also likes to see large rays and tyloses. Rays act as the channel for the flow of water and nutrients. Due to the way the cooper cuts the wood to create the stave of the barrel, the large rays make it difficult for the wine to diffuse out the sides of the barrel while providing flexibility and resilience. Tyloses develop when the tree is stressed or as the sapwood develops into heartwood. These are “plugs” to prevent further damage to the plant. It is like atherosclerosis for the tree- but is beneficial. For the cooper, it means no leaks. Tyloses allow for the watertight and airtight containers. These features are necessary for a superior quality cooperage wood.

The second post in this series will discuss the actual assembly process of the barrel. Hope you enjoyed reading.

~Slainte!

0 Comments